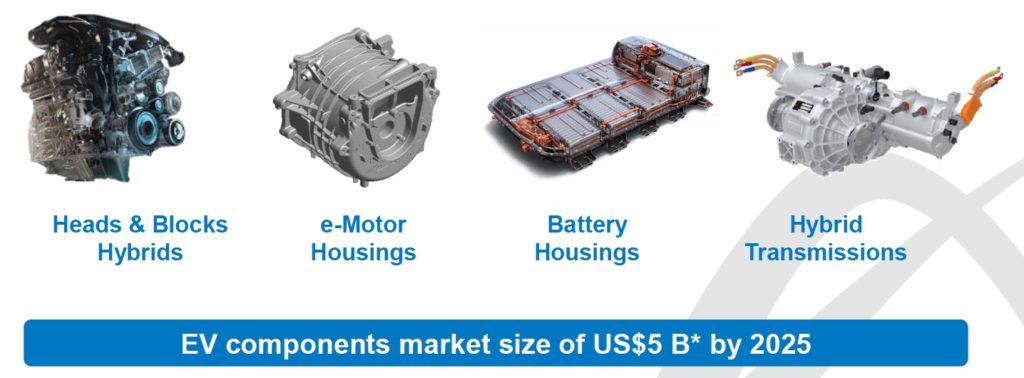

As plug-in electric vehicles begin to steal marketshare from internal combustion engines, what’s an engine block and cylinder head maker to do? Nemak, the giant global manufacturer of complex metal automotive components, is applying its expertise to specialized parts such as battery trays and electric motor housings that are critical to both passenger safety and battery performance in hybrid and electric vehicles.

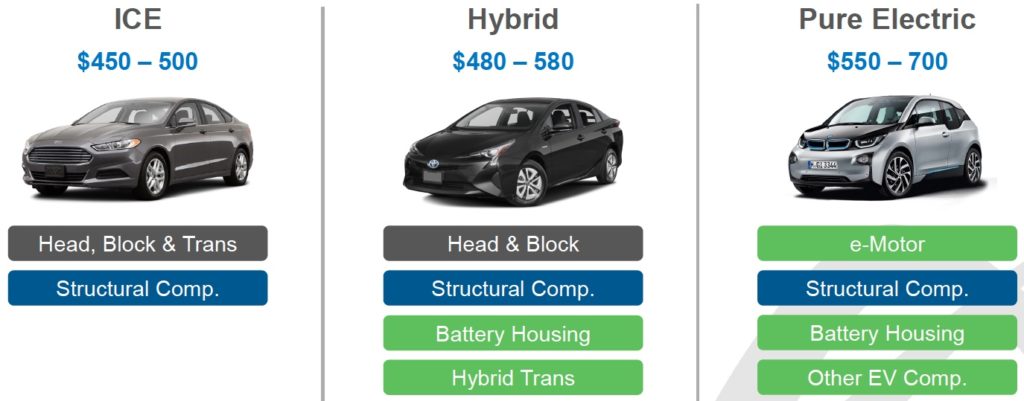

Minimizing weight is particularly significant for plug-in vehicles, and Nemak has already sold more than 3 million parts in this category resulting in annual revenue of approximately $400 million, or 10 percent of the company’s business. Not only are more cars requiring lightweight parts, but electric vehicles also present a bigger opportunity on a per-vehicle basis than traditional vehicles:

Because of this new business opportunity, “we decided to create an organization focused exclusively on driving execution and growth in [lightweight components and electric vehicles] — in addition to successfully ramping up production of these components, we are already seeing its contributions materialize in the form of cutting-edge innovations linked to vehicle lightweighting and electrification, primarily in battery, body-in-white, and chassis and suspension applications,” said Armando Tamez, Nemak´s CEO.

At its current pace, the company expects by 2020 that it will have a 20 percent share of the total U.S. and European market for battery housings for plug-in hybrid vehicles with annual sales of $1 billion by 2022 as more vehicles globally transition to electricity.

For more information about electric vehicles and electric vehicle charging, please contact me via my website or LinkedIn. I also invite you to subscribe to receive future posts via email, view my other posts, and follow me on Twitter.